Mankind's exploration of the universe at every step

all based on the achievements of materials science

Vectran

a thermogenic liquid crystal polyaryl ester fiber

Thermogenic refers to the liquid crystal state formed with the temperature increasing, existing in a certain temperature range. In addition to lyogenic liquid crystal (such as aramid fiber), refers to the liquid crystal state with the solvent, when the molecular concentration increased to a certain critical concentration.

Liquid crystal refers to the state of polymer aggregation, its molecular arrangement has characteristics of both liquid fluidity and solid arrangement in order.

Polyaryl ester refers to the chemical properties of Vectran, also known as aromatic polyester, which is a special polymer.

Vectran is considered to be the second generation of artificial super fiber after Kevlar and Twaron. Vectran was industrialized by Kuraray in 1990. Kevlar, the first generation star product of artificial super fiber, is the representative product of aromatic polyamide fibre also known as aramid fiber, which belongs to lytropic liquid crystals high performance fiber.

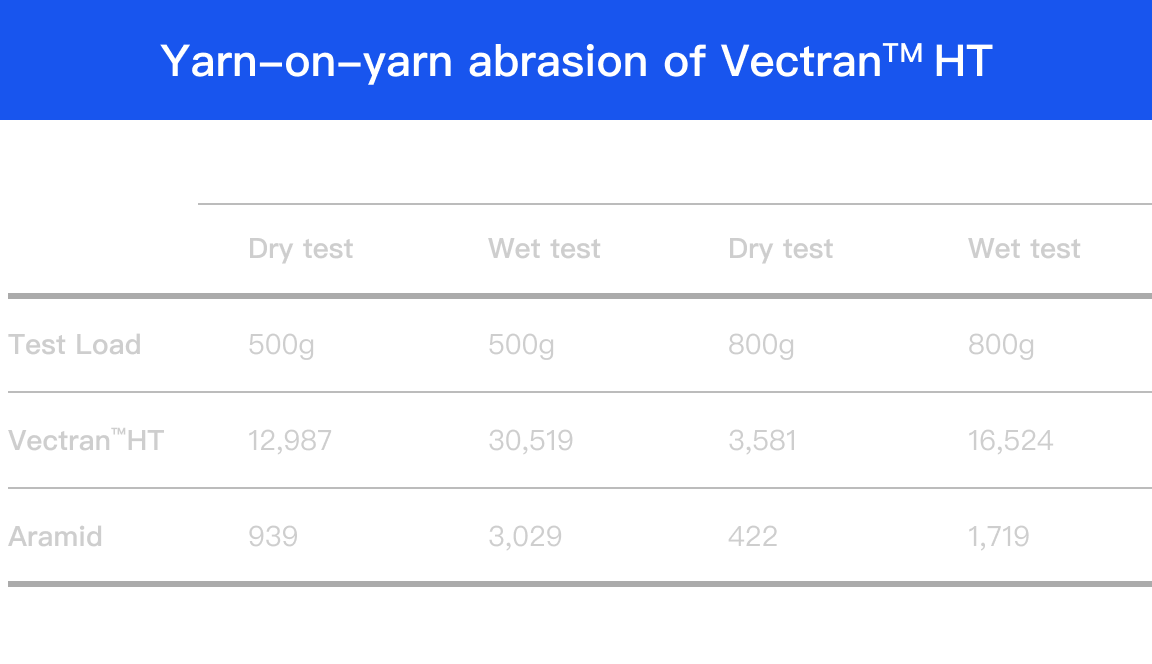

Vectran fiber and aramid fiber perform quite similar at mechanical properties and thermal stability. However, the resistance to creep properties, wear resistance, chemical corrosion resistance and strength retention rate at high/low temperature perform significantly better than those of aramid fiber.

(5% weight reduction temperature)

Reason to choose Vectran

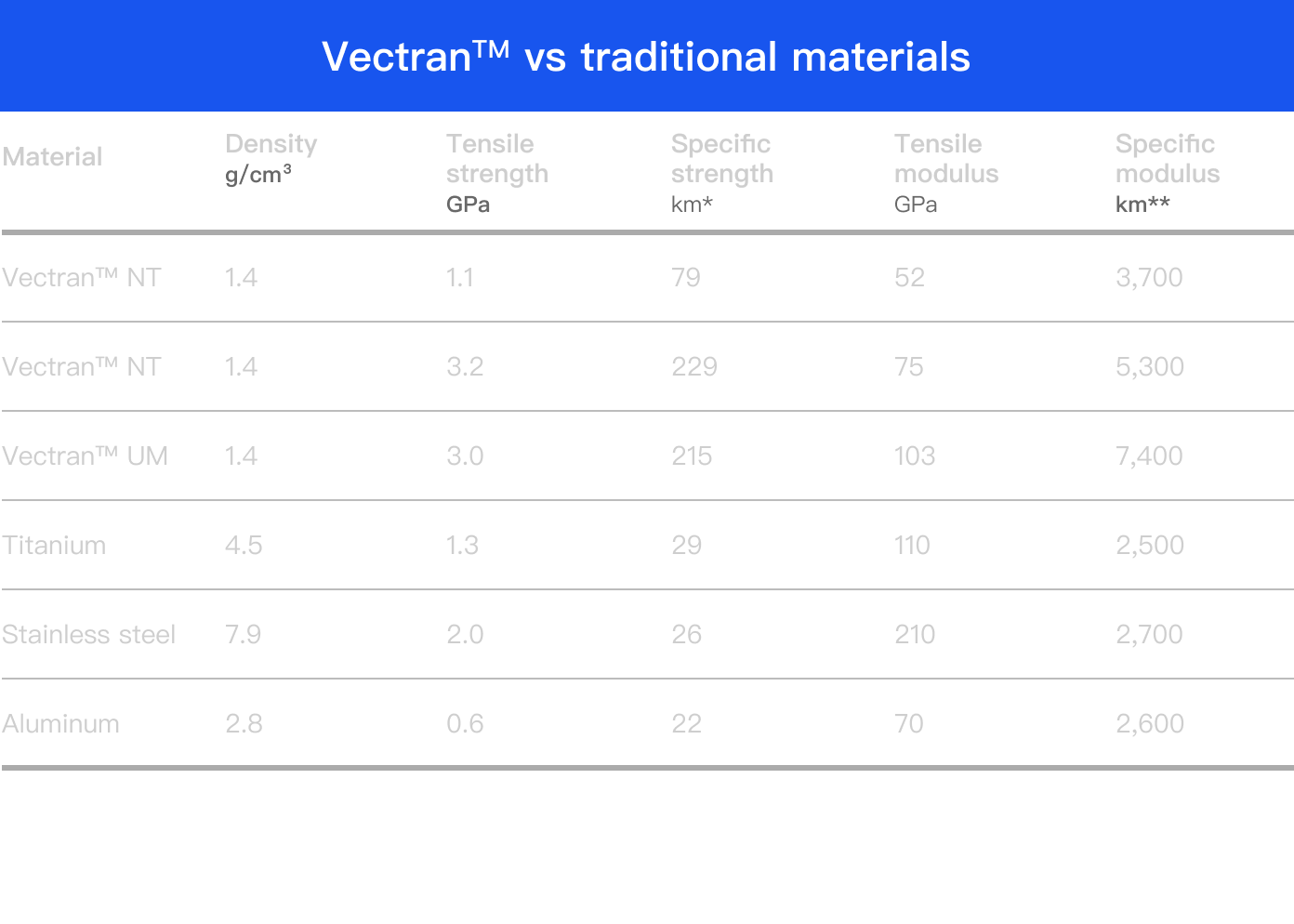

Lightweight

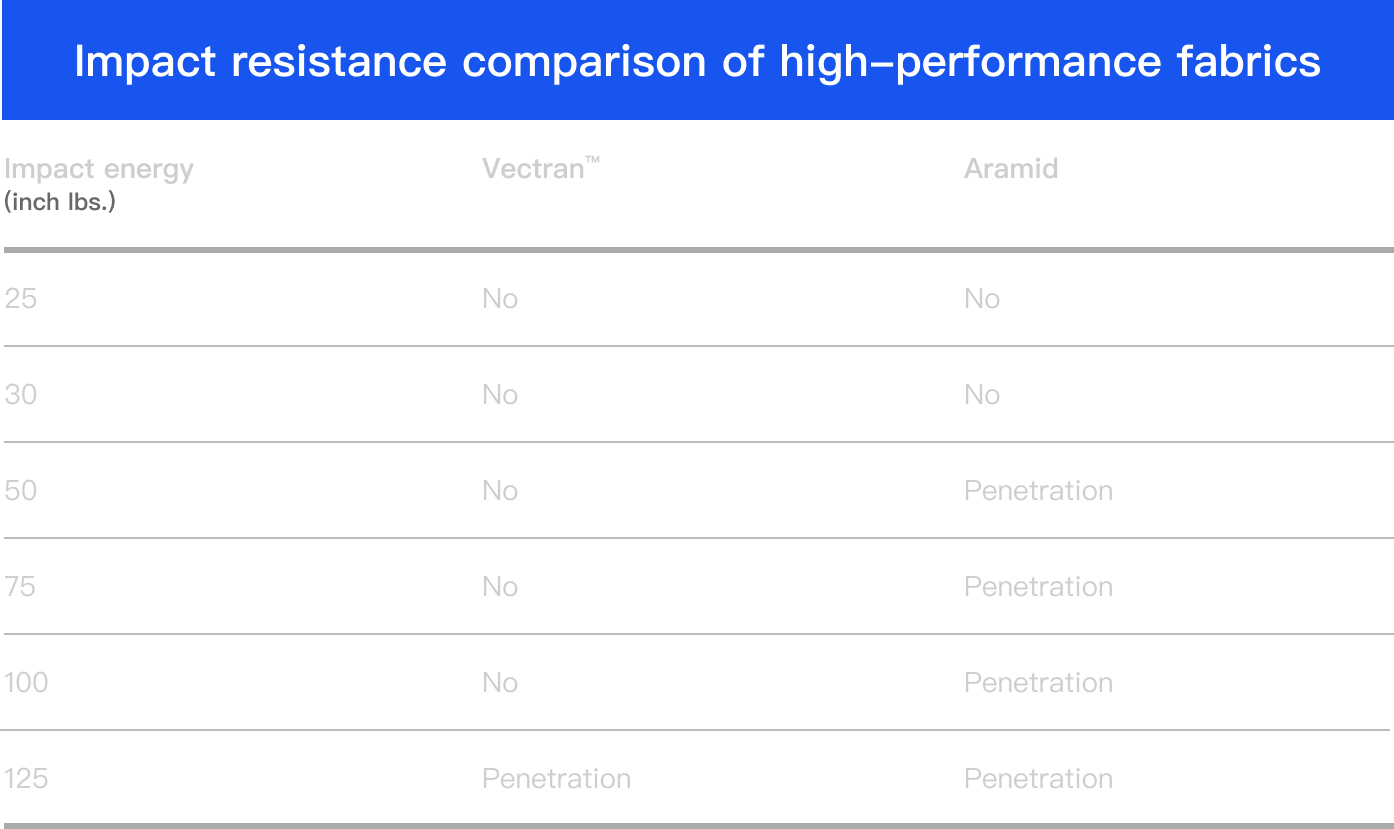

High impact resistance

High wear resistance

High resistance to bending

Excellent cutting resistance

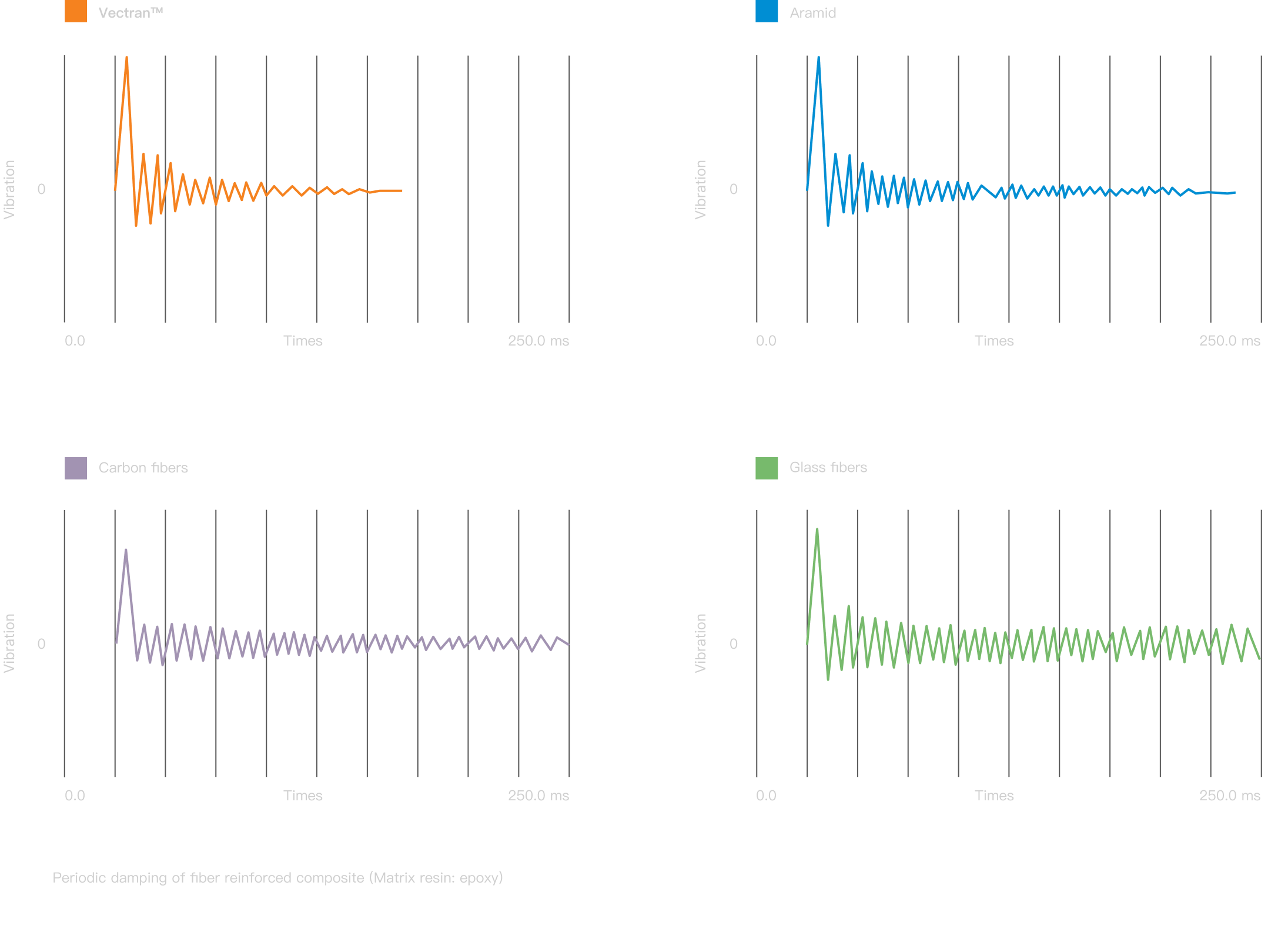

Vibration reduction

Excellent creep resistance

Excellent thermal performance

Excellent low temperature resistance

Resistance to chemical corrosion

Low hygroscopicity

Flame retardance

Resistance to radiation damage

Environmental protection

Field of Application

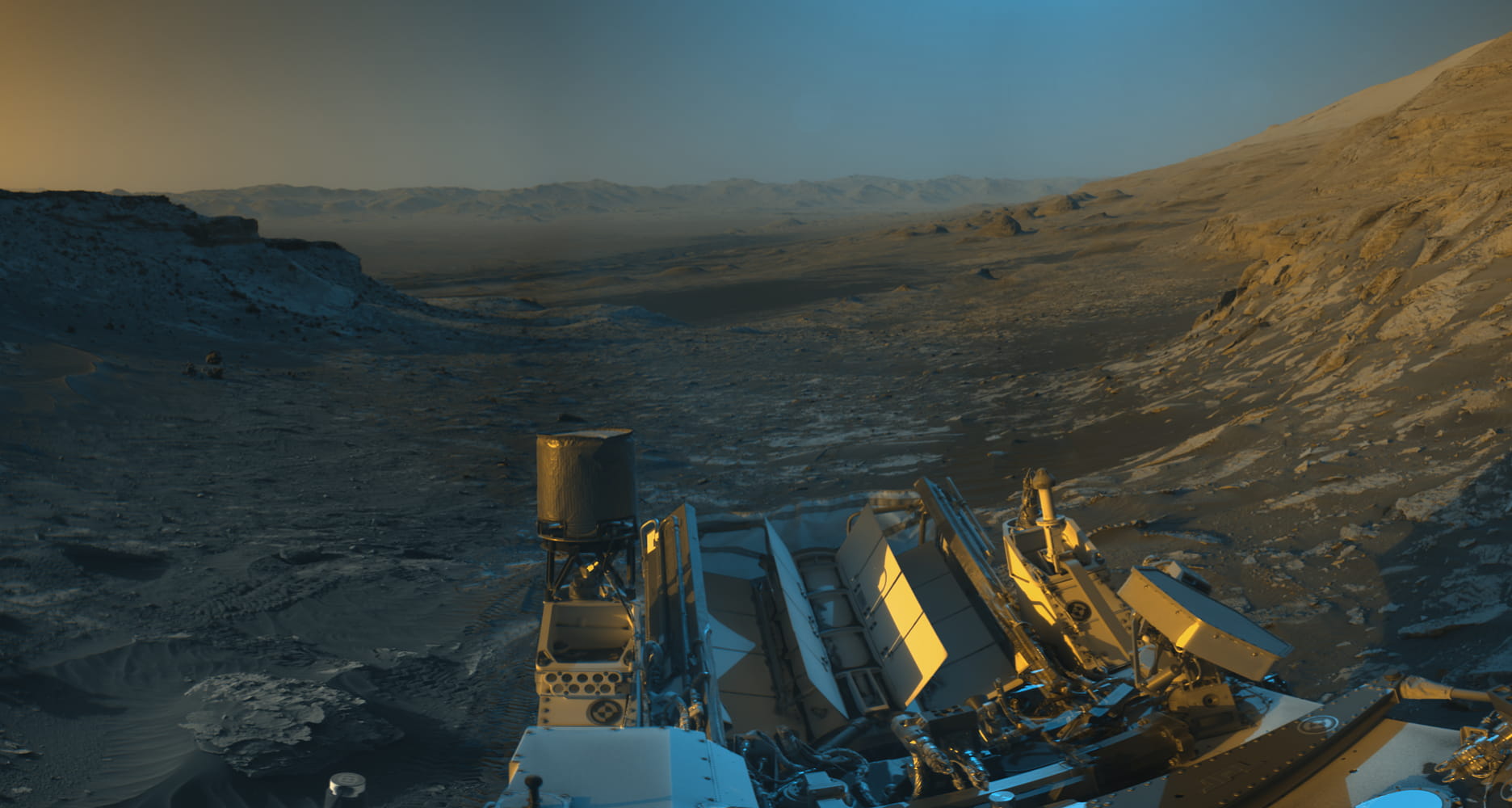

Vectran™ was used as the core material for the soft landing of Mars Rovers by NASA's Mars Pathfinder (MPF) program in 1997 and Mars Exploration Rover (MER) program in 2004.

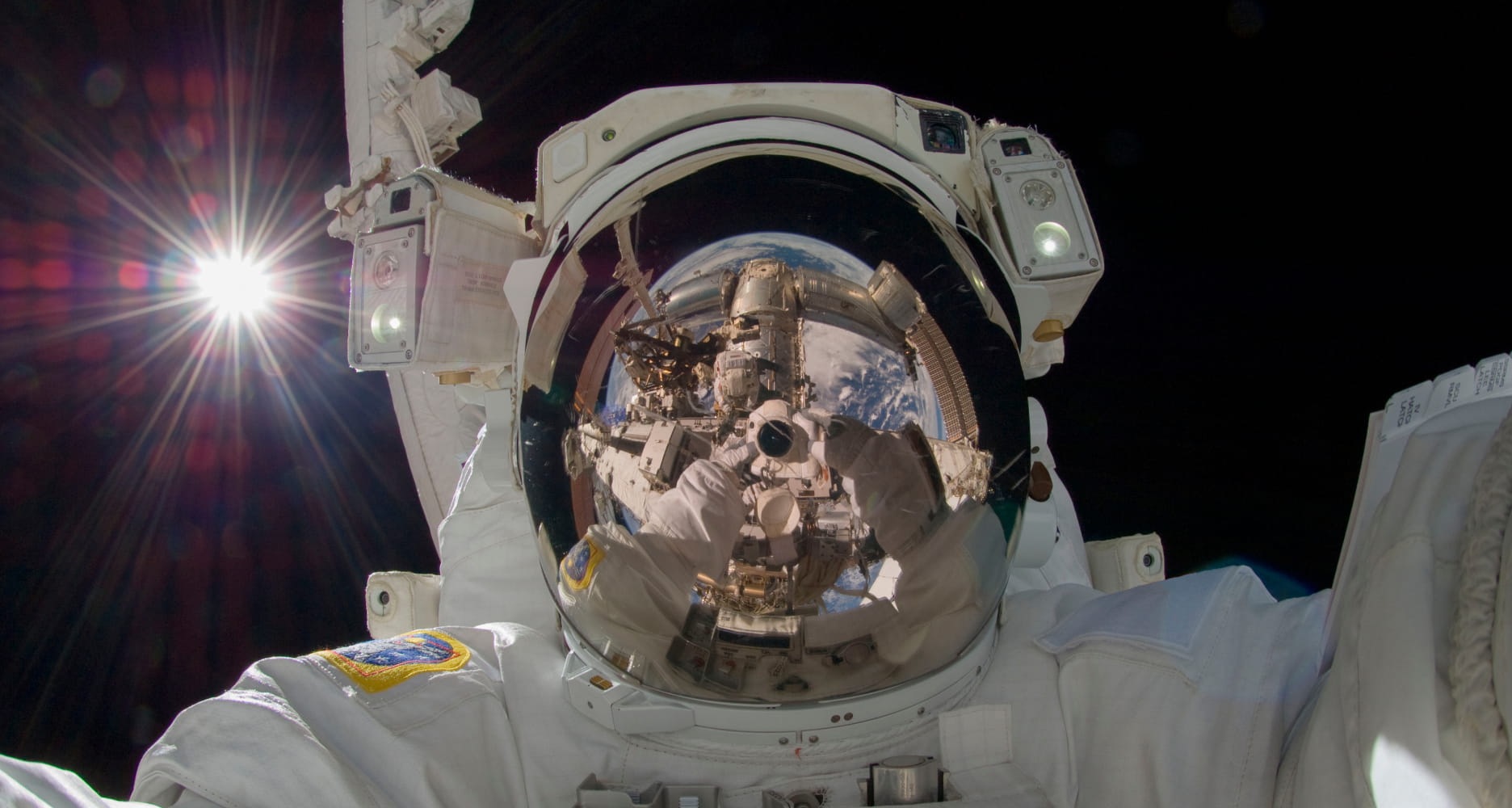

The Vectran™ is being used by ILC Dover as the I-Suit for the Space suit model.

Used as a fabric layer of the expandable Activity Module (BEAM) to test and validate expandable habitat technology, the Vectran™ may become a material for future expandable dwelling structures for deep space travel.

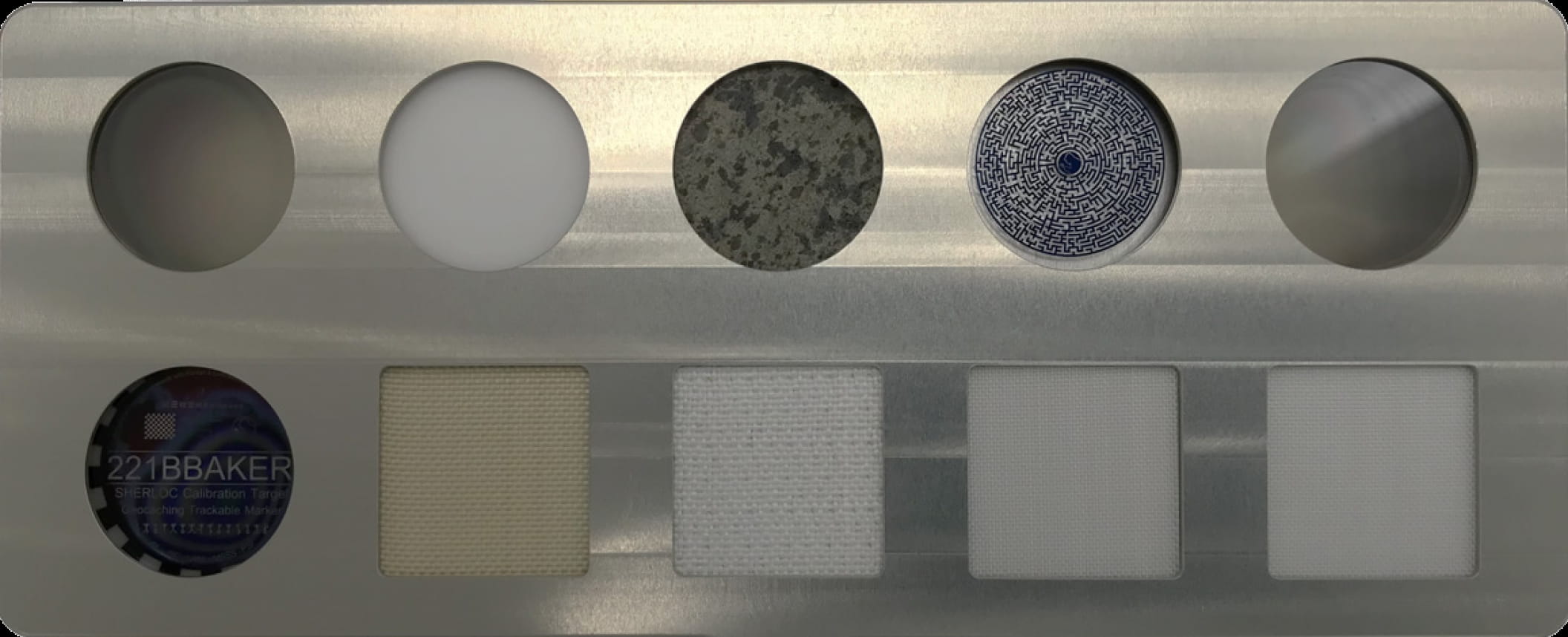

A small piece of Vectran™ is still being tested by the Martian atmosphere, and it could be the material for a Mars space suit for a future human landing on the Red Planet.

- [1] 李山,陈宏,郭金宝. 聚芳酯类热致液晶聚合物的研究进展[J]. 液晶与显示,2022,37(02):138-155.

- [2] 许进. 液晶聚酯纤维的研究和产业化进展[J]. 石油化工技术与经济,2021,37(06):51-55.

- [3] limeneh Derseh Yilie,Yilma Kelem Tiessasie. Article Review on Vectran-Super Fiber from Thermotropic Crystals of Rigid-Rod Polymer[J]. Journal of Engineering,2021,2021.

- [4] 赵忠政,罗培栋,王依民,宋丹,夏于旻. 热致液晶聚芳酯纤维的性能及其应用[J]. 中国个体防护装备,2020,(06):9-13.

- [5] ALAGNA C, IRFAN M, PERERO S, et al. Antibacterial nanostructured composite coating on high performance Vectran™ fabric for aerospace structures [J]. Surface and Coatings Technology,2019,373:47-55.

- [6] 覃俊,王桦,陈丽萍,岳海生,陈佳月. 芳香族聚酯液晶Vectran纤维的性能与应用[J]. 纺织科技进展,2017,(12):1-4.

- [7] PICKEN S J, SIKKEMA D J, BPERSTOEL H, et al. Liquid crystal main-chain polymers for high-performance fibre applications [J]. Liquid Crystals, 2011,38(11/12):1591-1605.

- [8] Tan K.T, Watanabe N, Sano M. Interlaminar fracture toughness of vectran-stitched composites-experimental and computational analysis [J]. Journal of composite materials, 2010, 44(26): 3203-3229.

- [9] 黄美荣. 液晶聚酯纤维的性能与结构[J]. 合成纤维,1998,(02):33-36.

- [10] 王睦铿. 热致液晶纤维新进展[J]. 材料导报,1994,(03):58-63+48.

- [11] Beers D E, Ramirez J E. Vectran high-performance fibre[J]. Journal of the Textile Institute, 1990, 81(4): 561-574.